Welcome to your ultimate guide to creating the perfect deck for your Omaha, NE haven!

Imagine summer barbecues with friends, lazy afternoons basking in the sun, and family gatherings under the stars – all on a beautifully constructed deck tailored to withstand Omaha’s unique climate.

Whether you’re a seasoned DIY enthusiast or embarking on your very first outdoor project, this article is your compass to navigate the world of deck hardware and fasteners.

Table of Contents

Must-Have Deck Components for Your Omaha Deck

When it comes to building a deck that can withstand the changing seasons and occasional Omaha storms, it’s all about starting strong.

The foundation of any great deck lies in its essential components, each playing a critical role in providing stability, safety, and longevity.

Let’s explore these must-have deck components that will ensure your Omaha deck stands tall for years to come.

Sturdy Deck Joists and Deck Beams

Think of joists and beams as the backbone of your Omaha deck. These components bear the weight of your deck and everything on it.

But what’s the best choice for your deck’s backbone?

In Omaha’s climate, where we experience both scorching summers and chilly winters, durability is key. You can opt for pressure-treated wood, which offers excellent strength and can handle Omaha’s temperature swings.

Alternatively, consider composite or steel options if you’re looking for materials that resist moisture, rot, and pests, ensuring a longer deck life.

Solid Deck Posts and Footings

Just like a sturdy house needs a solid foundation, your Omaha deck needs reliable posts and footings.

These elements anchor your deck securely to the ground, preventing shifting and sinking. Omaha’s freeze-thaw cycles call for materials that can handle stress.

Concrete piers are a popular choice, providing stability even in our unpredictable weather. Helical piles are another great option, penetrating deep into the ground to resist movement caused by frost heaves.

Attaching Safely with the Right Ledger Board

The ledger board is like the bridge connecting your deck to your home.

Ensuring a secure attachment is vital to prevent water damage and structural issues. To withstand Omaha’s climate, consider using corrosion-resistant fasteners like stainless steel lag bolts.

Additionally, use flashing to create a watertight seal between the ledger board and your home’s siding, protecting against moisture infiltration.

Omaha-Ready Railings and Balusters

Safety and style go hand in hand with railings and balusters. In Omaha, where we value safety and community, these components are not only essential but also offer a chance to express your deck’s personality.

Opt for materials like wood, metal, or glass that can endure Omaha’s weather while complementing your deck’s aesthetics. Be sure to adhere to local regulations for baluster spacing to keep your deck secure and up to code.

Decking Materials That Suit Omaha's Climate

The decking material you choose should be a perfect match for Omaha’s climate – capable of handling both the heat of summer and the chill of winter.

While wood decking provides a classic look, composite, PVC, and aluminum options offer excellent durability with minimal maintenance.

Composite decking, for instance, resists fading, staining, and mold growth, making it an ideal choice for Omaha homeowners seeking a long-lasting appeal.

Common Deck Hardware Components

Structural Screws

When it comes to securing critical connections in your deck, structural screws are your go-to solution.

These screws are specifically designed to provide exceptional holding power, making them ideal for fastening heavy components like beams, posts, and joists.

In Omaha’s climate, where temperature fluctuations and weather changes are the norm, using high-quality structural screws with corrosion-resistant properties is essential to ensure that your deck remains stable and safe over time.

Joist Hangers

Joist hangers play a crucial role in connecting the deck’s structural framework.

These metal brackets are designed to support the deck’s joists and keep them securely attached to the ledger board or the beam.

In Omaha’s climate, where temperature fluctuations are common, using galvanized or stainless steel joist hangers can help prevent rust and corrosion, ensuring the longevity of your deck.

Ledger Board Fasteners

The ledger board, attached to the house, is a critical component of a deck’s structural support.

Ledger board fasteners, such as lag screws or through-bolts, are used to securely attach the ledger board to the house’s rim joist.

Omaha’s varying weather conditions require strong fasteners to ensure the ledger board remains securely attached over time.

Deck Screws

Deck screws are specifically designed for outdoor use and are essential for securing decking boards to the underlying frame.

Using corrosion-resistant screws, such as those made from stainless steel or coated with specialized finishes, helps prevent deterioration due to moisture and weather exposure.

Deck screws come in various sizes and styles, allowing you to choose the right option for the type of wood you’re using and the local weather conditions.

Post Anchors

Post anchors provide a secure connection between the deck’s support posts and the concrete footings.

Omaha’s freeze-thaw cycles demand robust anchoring systems that can withstand the shifting of the ground.

Adjustable post anchors are particularly beneficial as they allow for fine-tuning the post’s height and alignment, ensuring stability and preventing sagging or tilting over time.

Railings and Balusters Connectors

Safety is a top priority when building a deck, and sturdy railings and balusters are essential to prevent accidents.

Railings and balusters connectors ensure that these components are securely attached to the deck’s frame.

Omaha’s weather can lead to expansion and contraction of materials, making it important to choose connectors that can accommodate these movements while maintaining structural integrity.

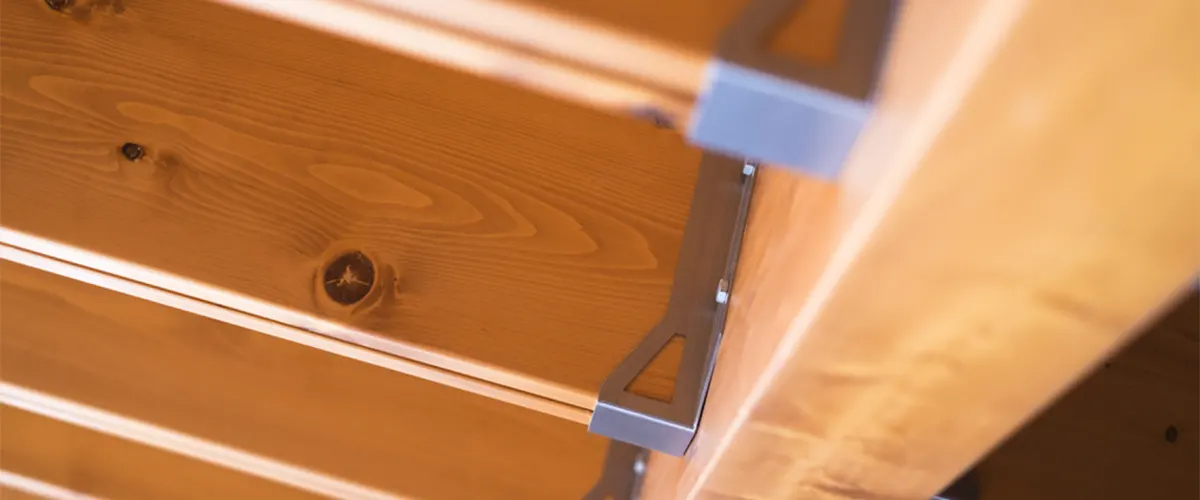

Brackets and Supports

Deck hardware like brackets and supports help reinforce critical areas of your deck’s structure.

Beam brackets, corner brackets, and post-to-beam connectors ensure that load-bearing components remain secure, reducing the risk of structural failure.

Choosing heavy-duty brackets and supports is particularly important for decks in Omaha, where they’ll need to withstand changing weather conditions and heavy snow loads.

Comparison of Deck Hardware Options

| Deck Hardware | Function | Material | Advantages | Considerations |

|---|---|---|---|---|

| Joist Hangers | Support joists and attach them securely | Galvanized or stainless steel | Prevents rust, ensures joist stability | Choose appropriate size for joist and usage |

| Ledger Board Fasteners | Secure ledger board to the house | Lag screws or through-bolts | Strong attachment, prevents ledger failure | Proper spacing and installation crucial |

| Deck Screws | Secure decking boards to frame | Stainless steel or coated | Corrosion-resistant, durable | Choose right size for decking material |

| Post Anchors | Connect support posts to footings | Various materials | Adjustable height, stability | Choose based on post size and load |

| Railings & Balusters Connectors | Secure railings and balusters | Stainless steel or coated | Enhanced safety, durable | Accommodate material expansion |

| Brackets & Supports | Reinforce key deck components | Various materials | Increased structural integrity | Choose heavy-duty options |

Deck Hardware Costs

| Part | Cost per Unit |

|---|---|

| Structural Screws | $2.50 |

| Joist Hangers | $1.75 |

| Ledger Board Fasteners | $1.20 |

| Deck Screws | $0.10 |

| Post Anchors | $3.00 |

| Railing and Balusters Connectors | $2.80 |

| Brackets and Supports | $2.25 |

Fasten Your Omaha Deck Right

Now that we’ve laid the groundwork with essential deck components, it’s time to dive into the world of fasteners – the unsung heroes that hold your Omaha deck together, ensuring its stability and longevity.

Choosing the right fasteners is crucial, especially in a climate like Omaha’s, where we experience a range of weather conditions.

Let’s explore the different types of fasteners and their applications to ensure your deck remains steadfast for years to come.

Nails

Nails have been a traditional choice for fastening deck boards due to their simplicity and cost-effectiveness.

However, they are gradually being replaced by more robust alternatives due to their tendency to work loose over time, leading to potential hazards and reduced structural integrity.

Omaha’s fluctuating climate with extreme temperature variations can exacerbate this issue as wood contracts and expands.

Deck Screws

Deck screws have gained popularity as a reliable fastening option due to their superior holding power and resistance to loosening.

In Omaha’s climate, where hot summers and cold winters are common, deck screws are a better choice as they can better withstand the wood’s natural movement.

Hidden Fastening Systems

Hidden fastening systems offer a sleek and clean appearance by attaching deck boards from beneath, eliminating the need for visible screws or nails on the surface.

These systems often include specialized fasteners, clips, or brackets that securely hold the boards in place while allowing for natural expansion and contraction.

Composite Decking Fasteners

For homeowners who opt for composite or synthetic decking materials, specialized fasteners are often recommended by manufacturers.

These fasteners are designed to accommodate the unique expansion and contraction properties of composite materials, ensuring a secure and visually appealing result.

Deck Fastener Types: Pros and Cons

| Type | Pros | Cons |

|---|---|---|

| Nails |

|

|

| Deck Screws |

|

|

| Hidden Fastening Systems |

|

|

| Composite Decking Fasteners |

|

|

Tips for Maintaining Your Omaha Deck Hardware

1. Regular Inspections

|

2. Prioritize Corrosion Resistance

|

3. Omaha-Appropriate Techniques

|

4. Adapt Hardware Choices

|

5. Regular Cleaning and Protection

|

6. Professional Inspection and Maintenance

|

Deck Hardware FAQs

Conclusion

Deck hardware is an extensive part of your deck building process. The materials need to be carefully picked, and you’ll have to make sure you’re doing everything in your power to build a deck that’s safe and sound for you and your loved ones.

At Deck Bros, we offer professional deck building services to all homeowners in Omaha Metropolitan Area. We proudly serve Gretna, Papillion, Bellevue, Elkhorn, Omaha, and the surrounding areas!

Give us a ring at (402) 369-5724 if you need more insights about your deck hardware, and let’s start your project together!